The global energy landscape is undergoing a profound transformation, with advanced battery technology at its epicenter. Beyond mere technological breakthroughs, a wave of evolving energy regulations is fundamentally reshaping the battery industry’s future, creating both challenges and unprecedented opportunities, particularly for U.S. solid-state battery (SSB) innovation.

Solid-state batteries represent a transformative leap in energy storage technology. Unlike traditional lithium-ion batteries, which use liquid electrolytes, SSBs rely on solid electrolytes that offer significantly improved energy density, safety, and longevity. These characteristics make them ideal for demanding applications — from electric vehicles and aerospace to defense and grid storage — where performance, reliability, and compact design are critical. As manufacturing scales and regulatory support accelerates, SSBs are poised to redefine the future of electrification across multiple sectors.

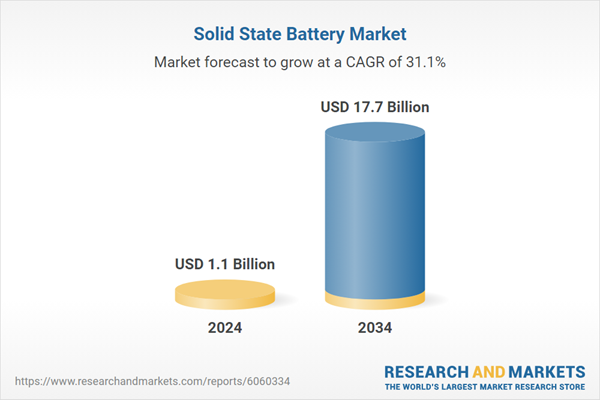

Market Momentum Meets Strategic Imperative

The numbers tell a compelling story. Already valued at over $1.1 billion in 2024, the global SSB market is on a remarkable trajectory, projected to reach $19.4 billion by 2034 and potentially $122.2 billion by 2037. As production scales for electric vehicles and defense applications, pioneering companies like Factorial are strategically positioned to lead this transformation and capture value in this rapidly expanding sector.

This explosive growth, however, represents only part of the narrative. National security considerations and supply chain resilience have triggered a strategic pivot toward domestic battery innovation. As advanced batteries become increasingly critical for both commercial and military applications, the U.S. government has intensified its focus on securing production and supply chains.

National Security Driving Domestic Innovation

The Department of Defense has emphasized that the Pentagon must source batteries from reliable, preferably domestic manufacturers with secure supply chains. Advanced batteries have become particularly critical infrastructure for ground transportation, drone, aviation, marine and energy storage. It has various strengths when it comes to military applications when it comes to high energy density, light weight, high power, broad temperature range of operations and quiet operations. Reinforcing this priority, the U.S. energy storage industry recently committed $100 billion to building and procuring American-made grid batteries, aiming to meet all domestic demand while strengthening national security. This creates distinctive opportunities for companies with robust domestic manufacturing capabilities and secure supply networks to fulfill these critical national requirements.

Evolving Trade Policies Creating Strategic Advantages

Recent trade policy developments have significantly reshaped the competitive landscape for U.S. battery manufacturers. In May 2025, the U.S. and China agreed to a temporary 90-day reduction of tariffs on battery-related imports. During this period, U.S. tariffs on Chinese battery imports dropped from up to 145% to approximately 30%, with effective rates on battery energy storage systems now estimated at 40–60%, depending on the product.

This temporary reprieve provides several key strategic advantages. First, it reduces short-term input costs for U.S. companies that still rely on Chinese components, improving margins and enabling faster production ramp-up. Second, it creates a window of financial flexibility that can be reinvested into scaling domestic capabilities, allowing companies to transition away from foreign dependencies more efficiently. Third, it gives U.S. manufacturers a stronger competitive footing in the global market by easing price pressures while maintaining long-term incentives to localize.

At the same time, federal initiatives such as the 45X advanced manufacturing production tax credit are reinforcing this shift by lowering the cost of domestic battery production and encouraging investment across the supply chain. Together, these policies are not just easing near-term pressures — they’re strategically positioning U.S. firms to accelerate growth, build resilient supply networks, and lead in the next era of battery innovation.

Economic Foundation for America’s Industrial Future

This emphasis on domestic manufacturing is vital to national economic strength, as batteries represent a foundational technology powering everything from unmanned aircraft and electric vehicles to aviation, marine transport, artificial intelligence, and data centers. Government support for manufacturing job creation and supply chain resilience not only strengthens these strategic sectors but also generates millions of high-quality jobs nationwide, further establishing batteries as a cornerstone of America’s industrial future.

Regulatory Tailwinds Accelerating Innovation

While scaling SSB technology for mass production presents challenges, the U.S. regulatory environment continues to grow more supportive. Federal incentives from the Inflation Reduction Act and the U.S. National Blueprint for Battery Innovation have played pivotal roles in accelerating domestic SSB manufacturing by streamlining permitting, offering tax credits, and supporting supply chains. Building on these foundations, the current administration has prioritized modernizing and expediting permitting processes to further reduce barriers for advanced manufacturing projects.

These combined policies are helping companies transition from pilot production to commercial scale more rapidly, making innovative SSB solutions likely to reach the market sooner than previously anticipated.

Pioneers Leading the Charge

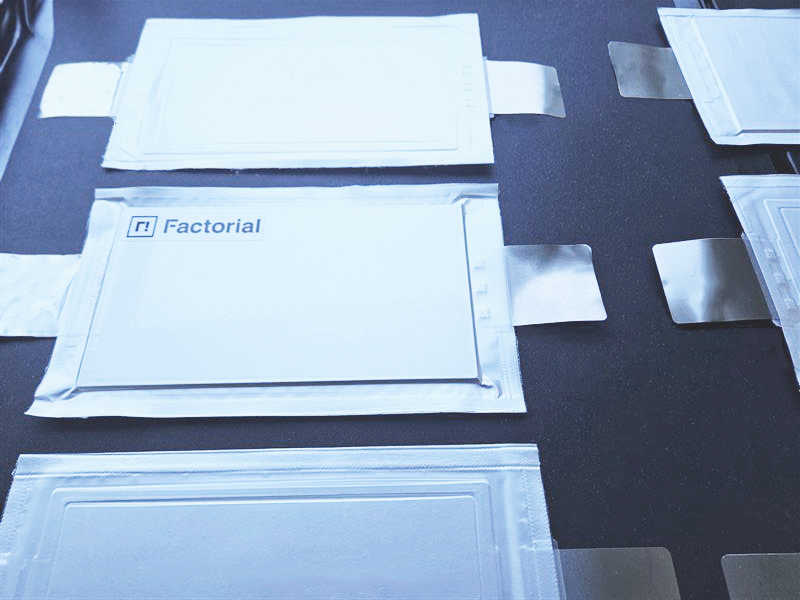

The U.S. solid-state battery industry stands at the threshold of unprecedented growth, fueled by a rapidly evolving regulatory environment and a national push for clean, secure, and domestically produced energy technologies. Companies that successfully navigate these changes — by prioritizing localization, diversifying supply chains, and capitalizing on federal incentives — are uniquely positioned to lead in powering America’s electrified future.

Factorial is proud to be among the pioneers driving this transformation, committed to advancing the next generation of battery innovation, one solid-state cell at a time. History has shown what’s at stake: lithium-ion batteries were invented in the United States but industrialized in Japan and mass-produced in China and South Korea. With solid-state batteries, the U.S. has a second chance — not just to compete, but to lead. This is our moment to leapfrog the incumbent technology and bring American innovation to the forefront of one of the most critical industries of the 21st century.