Billions are pouring into EV and energy storage manufacturing. Gigafactories are rising, partnerships are multiplying, and capital is chasing the next chemistry breakthrough. But behind the headlines and hype, one quiet, unsexy metric often determines who scales – and who stalls: yield.

Yield Isn’t Just a Technical KPI – It’s a Survival Metric

In battery manufacturing, yield refers to the percentage of cells that meet performance and quality standards without needing to be scrapped or reworked. It’s a direct reflection of cost, in terms of how tight your process controls are, how mature your product is, and how ready your operation is to scale.

And it’s ruthless.

A cell line operating at 10% yield isn’t just less efficient than one at 90% – it’s nine times more expensive, all else equal. That multiplier can crush even the most promising battery startup. Some haven’t failed because the chemistry didn’t work – but because the manufacturing couldn’t keep up.

Why Yield Expectations Change with Scale

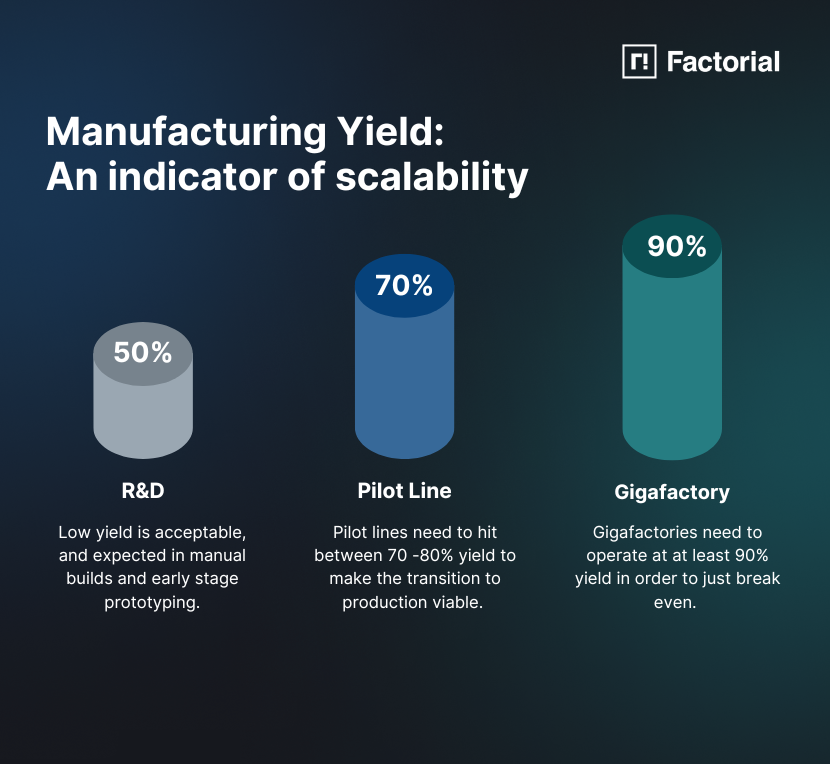

Low yield is tolerable in R&D. Manual builds and early-stage prototyping often see yields around 50%. It’s expected. But those figures don’t scale. For example, pilot lines need to hit 70–80% to make the transition to production viable. Gigafactories need to operate at 90%+ yield just to break even.1

Below that threshold, costs balloon, investors get nervous, and commercialization stalls. These aren’t arbitrary benchmarks – they’re dictated by physics, process complexity, and the economics of high-volume production.

Lessons from the Front Lines of Scaling

At Factorial, we’ve spent years moving from coin cells to manual pouches to automated pilot production. Along the way, we’ve learned what works – and what doesn’t.

Common pitfalls we’ve seen across the industry:

- Automating too early, before the chemistry or process is locked

- Scaling to satisfy investor timelines rather than engineering readiness

- Poor fit between cell designs and manufacturing equipment

- Premature supplier commitments that limit flexibility

What works better:

- Validating chemistry and cell design before committing to scale

- Moving intentionally from manual builds to pilot and production

- Letting process engineering – not market pressure – dictate pace

- Embedding data traceability from the beginning to catch issues early

At Factorial, we’re currently achieving ~85% yield at the pilot level – one of the highest rates among next-generation battery players, especially those working with solid-state and lithium-metal chemistries.

This wasn’t luck. It was built through a methodical, multi-year process:

- Starting with coin cells

- Progressing to manually assembled pouches

- Transitioning into fully automated pilot production

- Testing thousands of cells at each step to validate performance

We’ve applied lessons from legacy lithium-ion manufacturing while layering in traceability tools like GammatronTM to monitor material quality, process deviations, and system performance across every step of the production chain.

Why Yield – and Validation – Matter

Yield isn’t just for internal dashboards. For OEMs, it’s a critical sign of whether a battery technology is ready to move from pilot line to product line.

Our partners rigorously review yield data. They expect traceable performance metrics and consistent test results to ensure reliability at every stage. That’s why we’ve built internal validation programs that span both quasi-solid and all-solid-state architectures, identifying issues early – before they can derail scale.

In an industry that often celebrates “moving fast and breaking things,” we’ve chosen a different path: move deliberately, learn constantly, and scale with purpose.

When we began scaling our FEST® platform, we started at just 10% yield. Through focused engineering and a relentless commitment to process control, we’ve improved that to 85% – and we’re not done. As we introduce new materials, formats, and architectures, our core goal remains the same: engineer confidence, not just speed.

The Bottom Line: Yield Is the Real Indicator of Readiness

The battery world often talks in terms of energy density, range, and chemistry breakthroughs. But when it comes to commercial success, the metric that matters most might be yield.

For solid-state and other next-gen batteries, high yield is the linchpin that connects innovation to impact. And solving for it – patiently, deliberately, and rigorously – may be the defining challenge in battery manufacturing over the next decade.

- Yield numbers are assumed from the following sources:

https://seia.org/wp-content/uploads/2023/11/FINAL20SEIA20Energizing20Battery20Storage20Manufacturing20Whitepaper-Nov202023_0.pdf?

https://kpidepot.com/kpi/manufacturing-yield?

https://www.ffb.fraunhofer.de/en/press/news/the-ramp-up-of-a-gigafactory-in-battery-cell-production.html?

↩︎